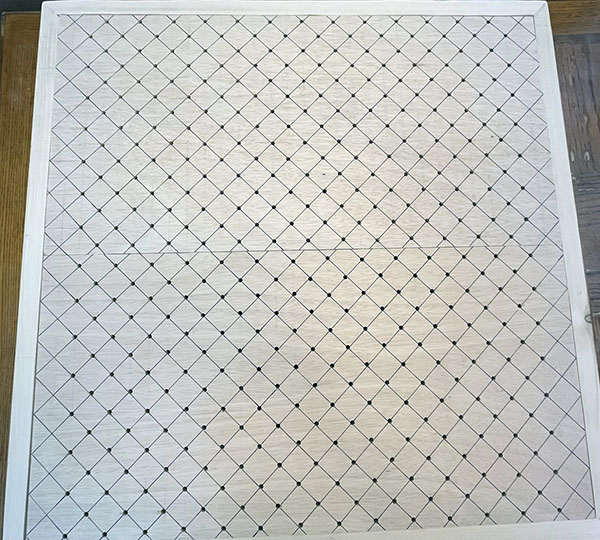

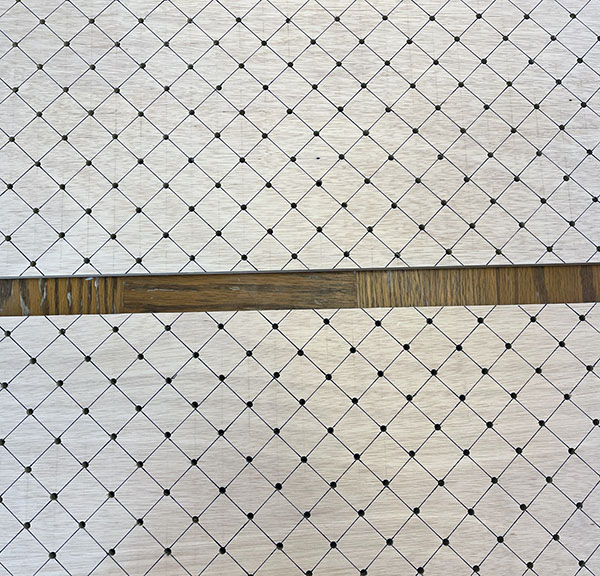

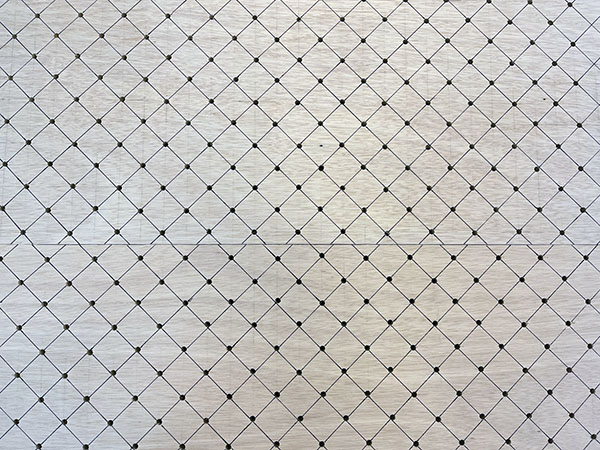

Making peg boards for my XL bobbin lace was an interesting process. Since there will be two boards, I had to figure out the positioning of the holes, so moving between the two panels will be seamless. The grid is a diamond shape, so I started and ended one panel with the holes on the outside. The other panel began and ended with the holes on the inside of the diamond shape.

The following pictures show the panels placed together. It should work quite well.

To keep the panels stable, a frame was made. I can use it for two grid panels or one with a grid and a spacer panel. It is important that I am not reaching up too high or working off the bottom of the panel, so the spacer helps move the working panel up to eye level.